This was a personal project to design a functional real world equivalent to Batman's armor. I took on this project as a challenge and as an educational experience to expand my skill-sets as a designer. The goal of the suit was to create a practical, modern style combat suit modeled after Batman's armor which would be durable enough for hand to hand combat against knifes, bats and other close combat weapons.

Being that this was such a large project and I was just a college freshman at the time, I knew I would need to reach out for external funding to be able to afford all the materials I planned on incorporating. I created a kickstarter campaign for the suit, which to my surprise actually reached its funding goal in just a week.

Being that this was such a large project and I was just a college freshman at the time, I knew I would need to reach out for external funding to be able to afford all the materials I planned on incorporating. I created a kickstarter campaign for the suit, which to my surprise actually reached its funding goal in just a week.

After a series of bench stress tests, I determined the protective materials I wanted to use to be 1/4" Kydex plating, Kevlar, and high density, closed-cell foam. I then started to prototype the sewing patterns and padding/plating layouts.

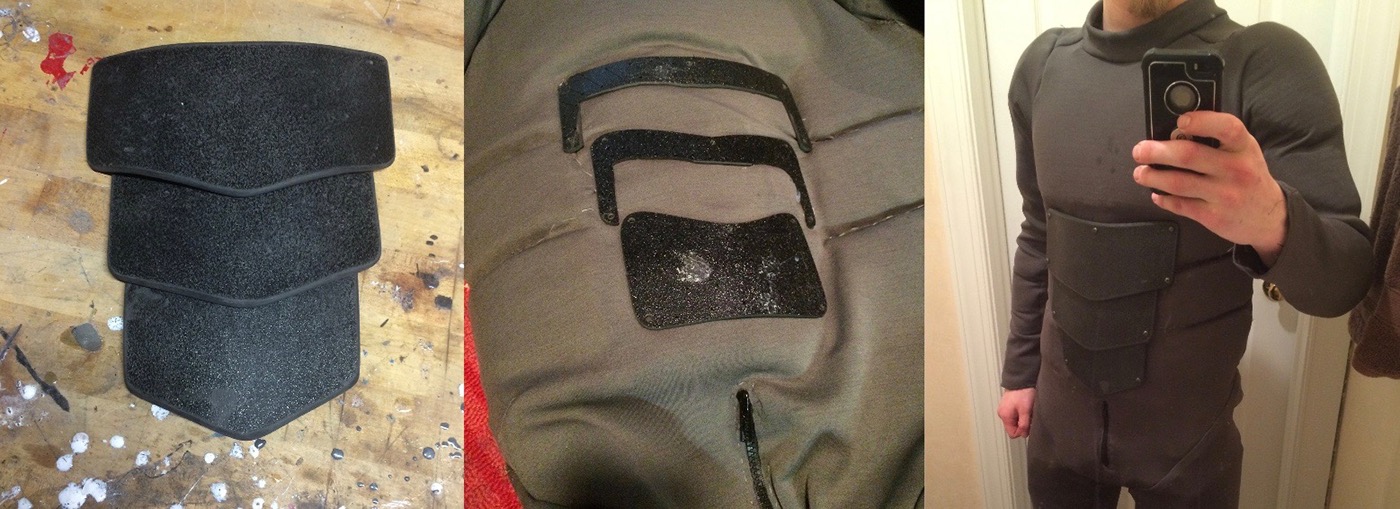

First Prototype

I quickly realized that a standard anatomical plating layout wouldn't provide nearly enough protection for real world application. I also determined that I would need to move the zipper to the rear to allow proper front padding.

Second Prototype

This version came out a lot cleaner, was more comfortable and very protective. I then shifted my attention to creating the cowl.

The Cowl

I decided I was going to make the cowl by hand from soft sheet plastic, form it to my liking, then mold and cast it from a durable impact resistant polyurethane. I started by forming 1/4" sintra around a pair of sunglasses, then hardened the inside using liquid urethane. Sheeting was added and built up to make the proper shape, then epoxy putty was applied and sanded uniformly to fill in the gaps and smooth out the surface.

Once I was satisfied with the form and fit, I created a two part box mold to replicate the cowl. A clay wall was used to divide the two halves, then silicone was poured into one half and allowed to cure, the clay wall was removed, then the second half was filled with silicone, completing the mold.

I used the mold to cast the final cowl from 65D, a special polyurethane made specifically for strength and impact resistance. This casting was cleaned up and painted, then attached to a kydex chin section with elastic, allowing for a comfortable and secure fit.

The Suit

I constructed the final suit in the same manner as the second prototype with the addition of Kevlar layers sandwiched between the inner and outer fabrics for cut resistance. Stretch panels were incorporated where needed to ensure the suit did not limit my mobility while remaining form fitting.

Once the sewing was all finished, I made the final set of Kydex plating and attached it to the main suit. The overlapping plate design allows the plates to flex in and out, allowing for mobility while retaining full coverage protection. The gauntlets, belt, and shin guards were made as removable pieces with attachment points to the main suit.

The Final Suit

News Coverage

After the completion of the suit, an article was published about it in USAToday which went viral, with over 200 websites reaching out to me for interviews and writing articles about the suit. Notable mentions among them are CNN, Buzzfeed and Time. I also did a number of TV interviews for several Discovery channel shows and news stations, and even went live on air on local Fox news to demo the suit.

Variations

After the all the publicity from the initial suit, I started my own company Armatus Designs and began making suits for clients on commission. Below are examples of some of the other suits I constructed.